Plastic Injection Molding Companies In Florida produce a variety of products for many industrial niches. They work with customers to provide cost-effective solutions without compromising quality.

They offer value-added services, such as a variety of finishing options, laser engraving, and paint. Their short lead times allow them to meet tight deadlines.

They also offer a range of resins and equipment for low- to high-volume production.

Custom plastic injection molding companies offer a wide range of services and solutions to meet your specific needs. Their engineers can help you select the best material for your product and create molds that will hold up to years of use. They can also assist you with design, prototyping, and testing. They can even provide a full line of finishing and assembly services for your finished products.

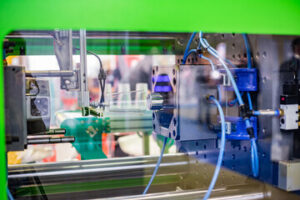

Injection molding can be used to produce parts of any size or shape, making it an ideal manufacturing process for complex products. It can also be used to make multiple identical copies of the same part, reducing costs and speeding up production time. It’s also environmentally friendly, producing less waste than other manufacturing processes and using biodegradable materials.

One of the most important things to look for in a plastic injection molding company is its level of sustainability. A company that prioritizes eco-friendly production methods is more likely to offer competitive prices and excellent customer service. They may also have a strong record of quality control and adherence to industry standards.

The flexibility of the injection molding process makes it easy to design unique and attractive packaging for your products. The ability to incorporate textured surfaces and customized features like snap-fit closures can add value to your packaging and increase consumer engagement. It can also help your brand stand out from competitors and improve customer retention.

A top-rated plastic injection molding company will have a dedicated team of project managers and engineers to assist you in every step of the production process. They can help you determine the best materials and design for your product, as well as optimize production costs. This will ensure that your final product meets your expectations and exceeds industry standards.

Injection molding is a great option for many different industries, including automotive, consumer electronics, and healthcare. Its versatility means that it can be used to create a variety of components for these industries, from simple plastic lids to more intricate and detailed parts. Its flexibility also means that it can be used to produce a wide variety of different types of plastic, from thermoplastics and engineering resins to elastomers and polycarbonate.

High-Quality Products

Plastic injection molding companies produce parts that are precise and accurate. They can even re-create complex geometries, and their advanced machinery allows them to maintain tight process control. For medical device manufacturers, this level of accuracy is critical because it translates into patient safety and the performance of the devices themselves.

To achieve this level of precision, the best plastic injection molding companies use a variety of materials to create the desired components and shapes. Some of the most common include polypropylene, polystyrene, and acrylonitrile butadiene styrene (ABS). These polymers can be manipulated to provide various mechanical, physical, and chemical properties, which makes them ideal for a wide range of applications.

Additionally, these materials are extremely durable and versatile. They can be used for both large and small parts, and they can be molded into many different shapes. They are also able to handle harsh environments on par with—or better than—many metal parts.

Injection molding companies also offer a variety of color options to meet specific aesthetic requirements. They can use masterbatches, which are concentrated pigments mixed into a resin, pre-colored resins, and salt and pepper blends to create the colors and finishes desired for their products. These color options can help make your plastic products more visually appealing and differentiate them from the competition.

One of the greatest benefits of working with an experienced plastic injection molding company is that they can help you save money by reducing the number of product iterations needed to get the right design and function. This is a result of the high level of automation and efficiency inherent in this type of manufacturing process.

In addition, the best plastic injection molding companies have strong technical strength and can collaborate closely with customers on product design and engineering to ensure that the finished component will deliver the necessary functionality. They also understand the importance of sustainable development and can incorporate energy-saving technologies into their production processes. This helps to reduce the environmental impact of the injection molding process, while simultaneously lowering production costs for their customers.

Cost-Effective Solutions

Injection molding companies can provide cost-effective solutions for a variety of manufacturing challenges. By leveraging the services offered by these companies, manufacturers can focus more energy and resources on the aspects of their business that are most important to them. This approach can help organizations achieve a competitive advantage by focusing their resources on what they do best, while outsourcing the areas of manufacturing that require the expertise and infrastructure that they don’t have.

In addition, injection molding is highly efficient and effective for high-volume production runs. The process is fast, scalable and produces parts with quality finishes that can reduce the need for post-production processes like painting or polishing. This can save a great deal of time and money, especially when working with large volumes of components.

Plastic injection molding also offers significant labor savings over other types of manufacturing. The process is largely automated, which minimizes human error and keeps production rates running smoothly. Additionally, the injection molds themselves are often reusable, which reduces production costs by allowing companies to quickly create new products with existing molds and tooling.

Another way that plastic injection molding helps companies save on labor costs is through its environmentally friendly manufacturing practices. The process uses relatively low amounts of energy, and any excess plastic generated can be recycled for future use. This is a significant benefit for companies seeking to reduce their carbon footprint and comply with environmental regulations.

When choosing a plastic injection molding company, look for one that has a system in place to recycle its excess plastics. The best eco-friendly injection molding companies have machines that grind up and reuse the sprues and runners that are created during the injection process, reducing waste and minimizing its impact on the environment.

Injection molding is ideal for creating a wide range of durable products, from large-scale HVAC and plumbing units to micro components for high-precision medical devices and wearable tech. The versatility of this manufacturing technique allows manufacturers to choose a plastic material that will suit their product’s specific needs and meet or exceed their quality and durability requirements.

Fast Turnaround

If you want your product to be available on the market as quickly as possible, then a plastic injection molding company that offers fast turnaround times is an excellent choice. This type of manufacturing process can help you meet your deadlines with ease, which can lead to greater productivity for your business. In addition, it can ensure that your products are of a high quality, which can also improve customer satisfaction.

Precision plastic injection technology inherently improves product quality. This is because it eliminates defects and dimensional inconsistencies, which helps to produce consistent results. This can significantly reduce the number of returns and complaints, and it may even increase customer trust in your brand. This can also reduce the overall cost of production.

Injection molding is an excellent manufacturing technology for producing mid to high-volumes of parts in both plastic and liquid silicone rubber. It is often the best option for projects that require high-strength and corrosion resistance. It is also an ideal choice for complex industrial parts and state-of-the-art medical components.

There are many different types of polymers that can be used for injection molding, including olefin ethylene and olefin propylene, acrylonitrile butadiene styrene (ABS), polycarbonate, and natural rubber. Each of these polymers has unique properties, so it’s important to consult with an experienced plastics designer when designing your product. This will help you create a design that is efficient and cost-effective for production.

When choosing a plastic injection molding company, it is vital to consider how long they have been in business. A reputable company will have years of experience and a proven track record. In addition, they will offer a range of services and provide a comprehensive solution for your project. They will work with you to ensure that your prototypes are ready for production, and they will use the latest technology to minimize costs and turnaround time. They also have a robust supply chain and are committed to delivering a quality product that meets your needs. This is why they have a dedicated team of project managers and a state-of-the-art facility.